**** NOTE WORK IN PROGRESS ****

Partly 3D printed wide-space capacitor for radiation detection

I wanted to make a wide-spaced air dialectric capacitor to use as a sensor to detect ions from weak radioactive sources.

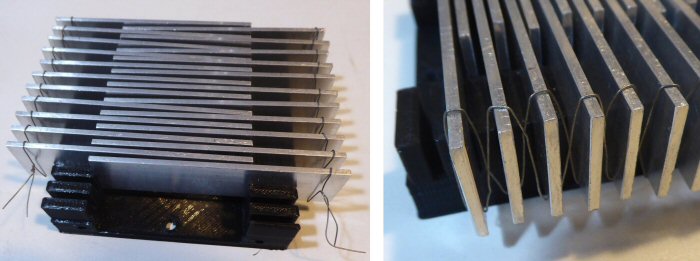

The capacitor was made from N aluminium sheets (vanes) held together using a 3D printed former.

The capacitor is made by sloting the Al vanes into the holder (see pictures and diagram).

There are N/2 sheets on each side and each set needs to be electrically connected together.

You can do this in various ways: 1) using two long 3 mm studing to go through holes at the ends of all the metal vanes and

2) a wire that loops around the vanes through the channel printed through the 3D former (not shown in the top picture).

3) perhaps the easest way is to wire the vanes together on each side useing a zig-zag of wire above and below each end of the vanes (see photos).

During desiging and making the capacitor I also made up a simple 3D printed drill-jig,

so that the aluminium vanes could all be accurately drilled,

and a 3D printed file-mitre (see links below) to polish and 'square' the vane ends.

So far I have made two versions:

i) N = 22 using 1mm vanes and

ii) N = 23 2mm thick vanes.

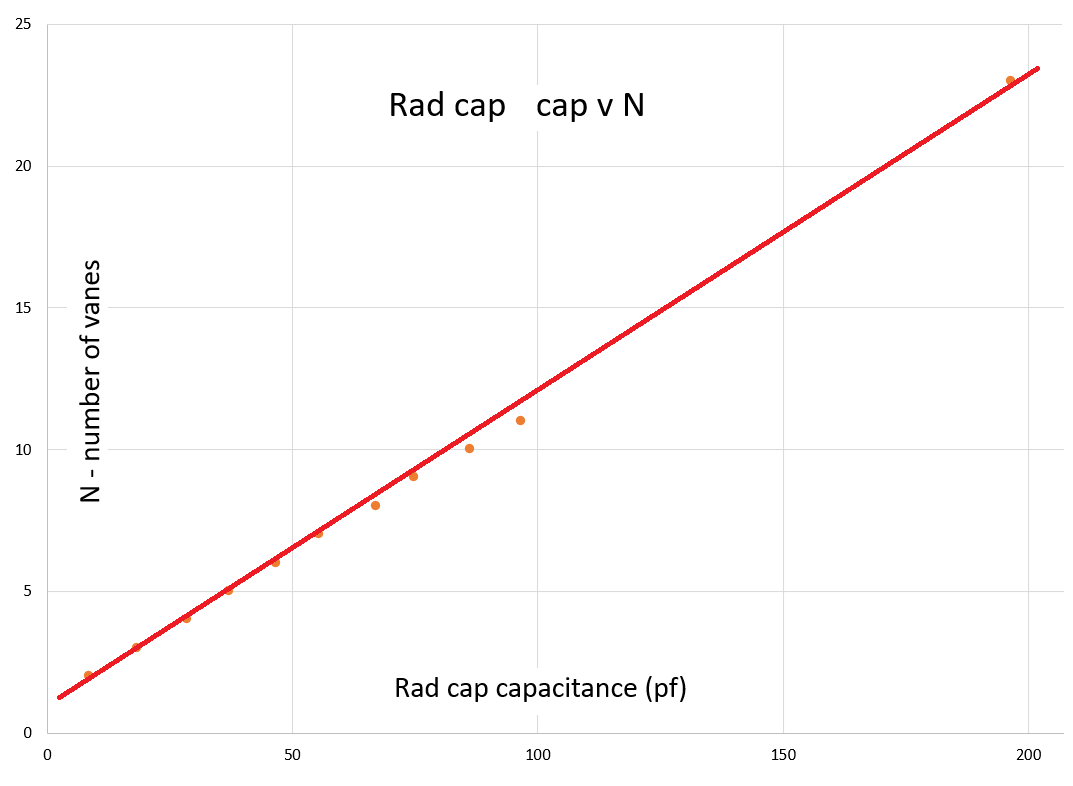

I measured the capacitance (pf) with different number of vanes (N) using a Peak Atlas LCR meter (ca. 200 kHz).

After N = 11, I jumped to N = 23.

3D printed device to hold the aluminium vanes of the capacitor

The table above shows the capacitance of the capacitor v number of vanes (see graph below).

N=2 is simply one vane on each side, N=3 is one vane on one side with two mounted either side of the first ...

Plot of N v capacitance (pf) showing a pretty good linear relationship.

|

drill jig |

file mitre |

".stl" file ".scad" file ".g" file |

more soon |

back to 3D page |

THE CREATIVE SCIENCE CENTRE

Dr Jonathan Hare University of Sussex, Brighton.

e-mail: j.p.hare@sussex.ac.uk

home | diary | whats on | CSC summary | latest news