The Discovery of C60,

Buckminsterfullerene & The Fullerenes

Introduction

C60, Buckminsterfullerene [1] the third allotropic form of carbon was

discovered in tiny quantities in 1985 by H. W. Kroto (Sussex Uni., UK) and

R. E. Smalley (Rice Uni., USA). In 1990 a method was developed to make C60

(and the family of carbon cage molecules - the fullerenes) in gram

quantities. Fullerene science has now become a rapidly growing field of

research [2]. This article briefly describes the fascinating experiments that first

uncovered the fullerenes and the subsequent techniques used to make bulk

quantities of them.

Cluster beam experiments

C60 and the fullerenes were discovered on a versatile and ingenious piece of

equipment called a cluster beam apparatus [1,2]. The beam experiments were

essentially very simple; an element (in this case carbon - graphite) was

rapidly heated (under vacuum or inert gas) by a high power laser, reaching

temperatures in excess of 10,000 °C - hotter than the surface of the Sun.

The vaporised products were then analysed using a sensitive mass

spectrometer. An additional refinement of the experiment was that the laser

vaporised products were rapidly cooled before being fed into the mass

spectrometer, this 'froze' out the reactivity of the various species

produced. Without this many of the species produced would rapidly go on to

form larger systems with their neighbouring vaporised atoms and molecules.

The technique therefore takes a sort of 'snap-shot' of the initial products

of the vaporisation.

The heart of the cluster beam apparatus was the mass spectrometer. This device separates out all the products in terms of their mass and displays the result in the form of a graph. This spectrometer makes the machine versatile and exquisitely sensitive. When carbon was analysed using this apparatus a whole range of structures (clusters of atoms) were observed, in fact the spectrum of carbon was one of the most interesting of all elements. Atoms, small molecules, large molecules, small particles, large particles and graphite fragments were all observed. At first sight it was obvious that a random mixture of products were produced by the laser vaporising the graphite. On closer inspection, certain sized clusters of atoms appear to be more abundant, stable and resistant to reaction than others. These 'magic' numbered species were shown to have the closed shell structures - the fullerenes - with C60, Buckminsterfullerene (the football molecule), usually being the most dominant [1,2].

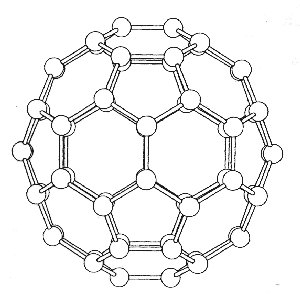

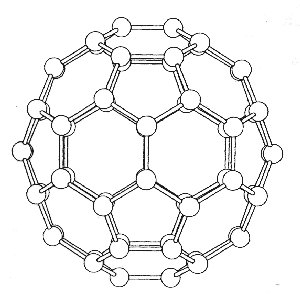

Analysis of the data suggested that the most reasonable solution was that the carbon molecules were forming closed cage structures. C60 has a particularly wonderful structure, that of a truncated icosahedron. The truncated icosahedron has 12 pentagon and 20 hexagon rings and has 60 vertices it is also the shape of the soccer ball football !

There was really only one problem in these fascinating and important experiments, and that was due to the amazing sensitivity of the spectrometer. You see, on the one hand this allowed the fullerenes to be first observed (under formation conditions that were probably far from favourable) but on the other hand it also meant that only tiny quantities were actually being produced at any one time. The machine was capable of detecting nanograms of C60. A rough calculation shows that even if one runs the cluster beam apparatus for ten years or so, - non stop - one would barely produce enough C60 to line the bottom of a test tube (perhaps only a few milligrams would be produced).

This amazing technology therefore puts us in a rather tantalising situation;

it allows us to make new discovers but then leaves us with the problem of

being able to make large enough amounts to be able to do anything with.

Therefore the promising new area of C60 science (for example the physical

and chemical properties) would have to wait until we could make large

quantities - at least on the milligram scale.

The carbon arc

The solution to this dilemma came about with the breakthrough made in 1990

by W. Krätschmer and D. R. Huffman (a German-American team [4]) and to a

certain extent the Sussex University team [2,5]) using apparatus that might

well have been available back in 1890 ! Unlike the expensive high-tech

cluster beam apparatus that discovered the fullerenes, the apparatus that

first produced gram quantities of C60 was incredibly simple. Bulk quantities

of C60 were first produced using a carbon arc. The technique works like this,

Two high purity carbon rods (roughly 5cm long and 0.5cm diameter) were supported so that their ends just touched. This rod system was mounted inside a glass bell-jar. The bell-jar was evacuated and filled with helium (or argon) to 100 Torr (roughly a seventh of an atmosphere pressure, 700 Torr = 1 atm). A large electrical current (20 volt at about 100 amps) was then passed through the rods, developing a bright arc-discharge between them. This was maintained for about 10 - 20 seconds during which time the arc sputters black soot like material throughout the jar. After letting the apparatus to cool down the bell-jar was opened up and the soot scrapped out.

The type of deposit found inside the bell-jar depends critically on the inert gas pressure. Under vacuum a hard, shiny brown graphitic layer was deposited which was difficult to remove. Introduction of only a small amount of inert gas dramatically changes the type of layers deposited. For fractions of a Torr of helium, the deposit settles as a fine jet-black powdery soot layer or film, which can be removed without difficulty. The soots remain jet black until the gas pressures reach c.a. 10 Torr, where the film develops a dark brown hue. On closer inspection these films appear to have a crystalline component, adding a slight sparkle to the dull soot layer. Similar results are obtained for argon, although the transition pressure is a little higher.

Providing the rods were fairly pure (better than a few % purity, ie. no

sulphur content) and that no air leaked into the jar during arcing, 5 - 10 %

of the soot produced in this arc treatment is actually C60. Its as simple as

that !

The fullerenes are soluble

The next step was to try and extract the fullerenes from the arc materials.

Adding toluene (or benzene, hexane, chloroform, carbon disulphide etc) to

the soot and leaving the resultant mixture to stand for a few hours, we find

that the fine suspension of soot particles will settle and the solvent will

have turned red (this was first done at Sussex 6 August 1990, [2,17]). Mass

spectrometry shows that the solution contains C60 and larger fullerenes.

Solvent extraction of the fullerenes is therefore possible. Analysis shows

that C60, C70 and traces of the larger fullerenes make up roughly 80, 20 and

less than 1 % of the isolated material respectively [5].

It is this solubility which allows the fullerenes to be separated

effectively by chromatography (see below) and enables chemical reactions to

be studied systematically and conveniently.

Improving extraction - soxhlet method

Improved fullerene yields were obtained using an ingenious device called a

Soxhlet extractor [5,6]. The soot was loaded into

a thimble (typically ca. 2 - 3 g of soot; 100 x 30 mm thimble) and placed

into the extractor. Hot solvent condenses and drops on to the soot,

dissolving the fullerenes. Eventually a siphon arrangement draws the

saturated solution away so that a fresh batch of solvent can further extract

the soot. In this way the maximum amount of soluble material can be

extracted. Because of the toxicity of benzene one generally uses chloroform

or toluene. Although fullerene solubility might be slightly lower in these

solvents it does not hinder the extraction process significantly because the

soot is washed many times. Extraction of c.a. 3 grams of soot takes about 2

- 3 hours, and is judged to be complete after the colour stops leaching from

the thimble (although small traces of the larger fullerene > C70 may well

take 10's hours to remove completely). Using this method 5 - 10 % of the

soot was found to be soluble, where the majority of the extract are

fullerenes. The extract solution can then be evaporated to give a

brown-black solid. This extract is washed in acetone to remove hydrocarbon

impurities which may be present from the solvents.

Chromatography

Having found that the extracted material consists of a mixture of molecules

their separation was achieved at Sussex by column chromatography [2,5,6,7].

A chromatography column (glass tube ca. 30 cm long x 1 cm diameter, glass sinter + tap) was filled with carbon granules (Elorite grade see [19]). The bottom tap was opened and toluene added until the level reached the top of the granules and no more was absorbed. The concentrated extract (ca. 30 mg in 100 ml of toluene) was then passed down the column. When all the extract was loaded onto the column, fresh toluene was applied. After roughly 10 minuets (from first applying the extract) the first coloured fractions should emerge from the column. This band is a beautiful magenta colour and consists of pure C60. Very soon after the first coloured fraction has finished, a second band appears that is red. This fraction is a mixture of C60 and C70 (the colour of the former is masked by the latter).

Using this technique, pure samples of C60 can easily be prepared. However

the red C70 fraction will still contain C60 and so further chromatographic

separation has to be carried out on these fractions to produce pure C70.

Chromatography of large amounts of extract (ca. 100 mg) also produced other

weakly coloured bands following the C70 fractions. These are due to higher

mass (larger) fullerenes present at very low concentrations (ie. see

reference [8] for examples of larger fullerenes greater than C70)

Further Purification

After repeated chromatography, solutions of relatively pure C60 and C70 can

be prepared (better than 95 % pure by spectroscopy). The solvent can be evaporated to

leave the solid fullerene. However, the dry solid still contains a

significant quantity of solvent trapped in the crystal lattice.

For example, IR (Infrared) spectroscopy of thin films of C60, show benzene

peaks when evaporated from this solvent. Whatever solvent one uses there is

always trapping in the crystal lattice (perhaps a few % of the mass). One

can substantially reduce this by baking the fullerenes at 550 K for several

hours under vacuum (less than 1/1000 Torr). However, defect-free samples of the

fullerenes can only be made by subliming the samples (i.e. heating at ca.

800 K and collecting the sublimate) and then heating for days at a constant

temperature (c.a. 600 K) under vacuum. In this way samples can be annealed

to produce material of high quality.

return to C60 page

return to 'Things to Make' page

References, notes and diagrams

Scientific articles and notes (articles = name, Journal, year, vol., page)

[1] H. W. Kroto, J. R. Heath, S. C. O'Brien, R. F. Curl, R. E. Smalley,

Nature, 1985, 318, 162.

[2] H. W. Kroto, C60: Buckminsterfullerene, The Celestial Sphere that Fell

to Earth,

Angewandte Chemie, 1992, 31, 111 - 246.

[3] J. P. Hare, Sussex University, C60 and Schools, Past Sixteen Science

Issues, Feb. 1996.

[4] W. Krätschmer, L. D. Lamb, K. Fostiropoulos, D. R. Huffman, Nature,

1990, 347, 354.

[5] R. Taylor, J. P. Hare, A. K. Abdul-Sada, H. W. Kroto, Journal of The

Chemical Society,

Chemical Communications, 1990, 1423.

[6] J. P. Hare, R. Taylor, H. W. Kroto, Chemical Physics Letters, 1991, 177,

394.

[7] A. D. Darwish, H. W. Kroto, R. Taylor, D. R. M. Walton, Improved

chromatographic

separation of C60 and C70,

Journal of the Chemical Society, Chemical Communications, 1994, 15 - 16.

[8] See articles in Physics and Chemistry of Fullerenes, Editor P. S.

Stephens,

Advanced Series in Fullerenes, Vol. 1, World Scientific Publications, 1993,

ISBN 981-02-1117-1.

[9] A vertical rod-block generator with a large volume (ca. 10 litre)

stainless steel chamber.

[10] R. E. Haufler, Materials Research Society, Symposium Proceedings, 29th

Nov. 1990.

[11] D. H. Parker, P. Worz, K. Chatterjee, K. R. Lykke, J. E. Hunt, M. J.

Pellin,

J. C. Hemmiger, D. M. Gruen, L. M. Stock, Journal of the American Chemical

Society, 1991, 113, 7499.

[12] A. S. Koch, K. C. Khemani, F. Wudl, Journal of Organic Chemistry, 1991,

56, 4543.

[13] G. Peters, M. Jansen, Angewandte Chemie, International (English)

Edition 1992, 31, 223.

[14] R. E. Haufler et al. Material Research Society, Symposium Proceedings,

1991, 206, 627 - 637.

[15] K. Yoshie, S. Kasuya, K. Eguchi, T. Yoshida, Applied Physics Letters,

1992, 61, 2782.

[16] W. A. Scrivens, J. M. Tour, Journal of Organic Chemistry, 1992, 57, 6932.

[17] J. P. Hare, PhD Thesis, University of Sussex, Chemistry and Molecular

Sciences, 1993.

Carbon rod suppliers

[18] Le Carbon, South Street, Portslade, Brighton, East Sussex, BN41 2LX.

Tel. 01273 415701, Fax. 01273 415673. Purity 6 rods,

4.6 mm diameter x 303 mm long, ca. £ 200 for 100).

Agar Aids Ltd, 66a Cambridge Road, Stansted, Essex, CM24 8DA

(for small high purity rods, Type E340, 5 mm diameter x 50 mm

ca. £10-00 for 10).

Chromatography suppliers

[19] Toluene need not be high purity.

Fissons may sell an appropriate column

Carbon granules from;

Norite Ltd, ELORITE grade, carbon granules, sample number A-8160, Norit

N. V., Postbus 105, 3800 AC, Amersfoot, The Netherlands.

AC welding power supplies

[20] RS components, Turboweld 8, SN 623-271, page 3-3125 Radio Spares Catalogue

or borrow one , have one donated, or steal one from a builder, ironmonger

or garage.

or try a fully charged car battery.

home | diary | whats on | CSC summary | latest news